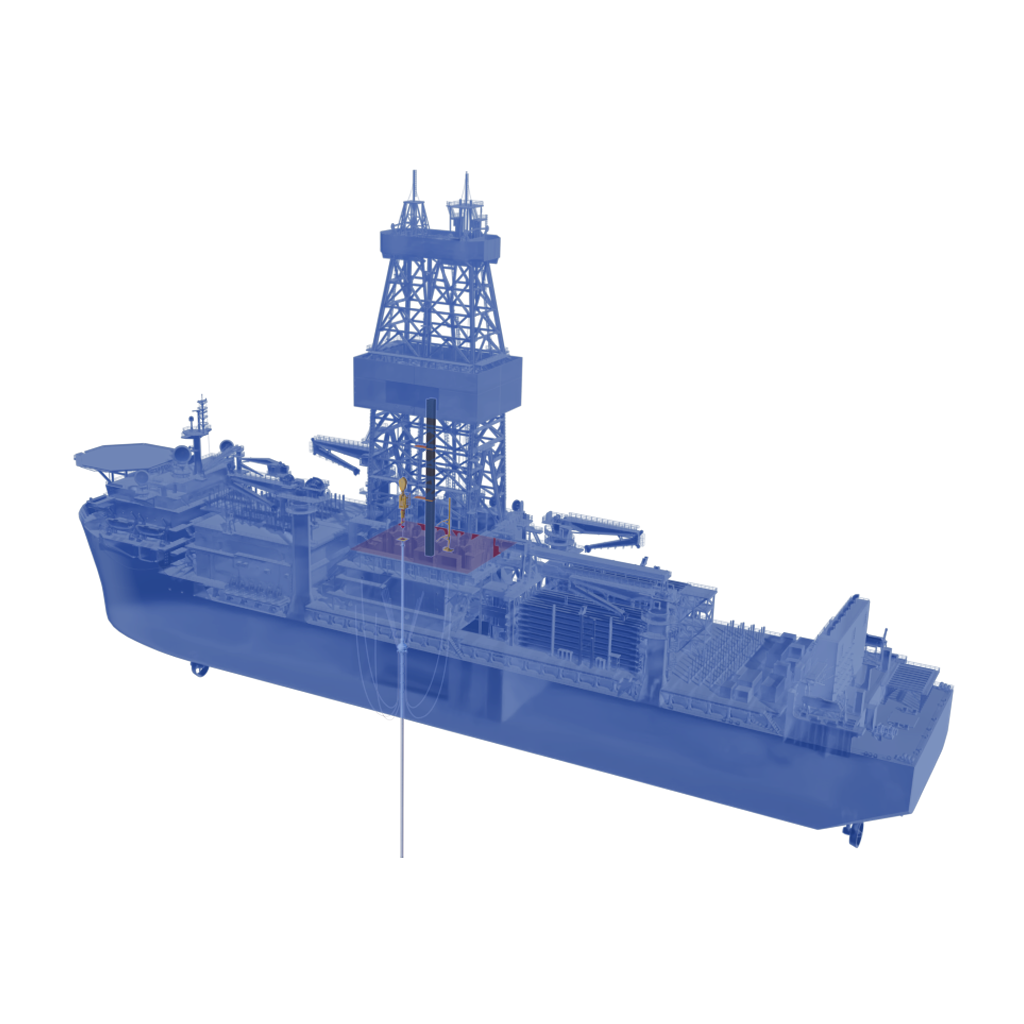

Back to the Rig

WITH FIVE KEY SAFETY TECHNOLOGIES:

DRILL PIPE WIPER, FINGERBOARD MONITORING SYSTEM,

AUTOMATED GOOSENECKS, RED ZONE MANAGEMENT,

AND STANDARD OPERATING MANUAL (SOM).

CLICK THE HOTSPOTS TO EXPLORE

Safety Technologies

Advanced technologies, standardization of safety procedures across our fleet, and world-class training programs reduce safety incidents and operational downtime, optimizing performance and efficiency. Our advanced technologies and ways of working help to safeguard crew members by automating manual activities. These benefits extend beyond our offshore crews to our clients, who benefit from safer, more sustainable, and cost-efficient operations.

Drill Pipe Wiper

Integrated to the diverter housing, the Drill Pipe Wiper removes personnel from the Red Zone, improving safety on the drill floor.

Discover more

Fingerboard Monitoring System

Seadrill’s fingerboard monitoring system integrates with OEM equipment and provides fingerboard latch status in real-time.

Discover more

Red Zone Management

The Red Zone monitoring solution constantly monitors people and equipment in the Red Zone.

Discover more

Automated Goosenecks

The Hands-Free Gooseneck System (HFGN) improves safety and efficiency by removing manual intervention below the drill floor.

Discover more

Standard Operating Manual (SOM)

The Seadrill Standard Operating Manual standardizes operations across our fleet, providing a set of procedures and checklists focused on reliable and effective execution.

Discover more